For more than 140 years, clay mining was a major industry in West Virginia. Bricks for buildings and streets, tiles and pottery were manufactured from clay mined from residual clays developed by the weathering of limestone and shale and from transported clays deposited in rivers and swamps during the marine geologic age. These clay deposits are widely dispersed in West Virginia and were used by many individuals to make clay products, such as bricks for their own homes during the 19th century. In addition, many counties had large scale clay mining that spawned clay product industries. For instance, clay was mined in Berkeley County by the United Clay Products and Continental Clay Products; in Cabell County by the Barboursville Clay Manufacturing Company; in Kanawha County by the West Virginia Brick Company and the Charleston Vitreous Clay Products Company; in Lewis County by the Weston Brick and Coal Company and the Jane Lew Brick and Drain Tile Company; and in Marion County by the Colfax Brick Company and the Hammond Fire Brick Company.

While seams of clay are found throughout West Virginia, the clay in the Northern Panhandle historically was not only plentiful but also of exceptional quality because of the fineness (smallness) of its particles. Hancock County clay is of sedimentary origin, which means it is usually associated with coal and shale. In the early days of clay mining in Hancock County, the three-foot-thick seam of coal on top of the clay was ignored by miners more intent on reaching the high-quality clay for brick and pottery making.

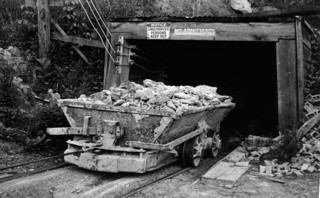

Nowhere in the state did clay mining reach the scale it did in Hancock County, which for a number of years, was the brick and tile capital of the United States. Clay was first mined in Hancock County about 1830. Eventually more than a dozen companies were manufacturing bricks, sewer pipe, pottery, and specialty items such as chimney tops, terra cotta vases, and furnace linings from local clay and shale. A thriving pottery industry began in the same period and continues to manufacture dishes and tableware today. In the mid-19th century, the same workers who mined clay by hand in the winter made bricks or other clay products in the summer. They pulled clay out of the mine in carts over wooden stringers and dumped it into piles. When used for bricks, the clay was pushed through rollers several times to grind it to sufficient fineness, mixed with water in the ‘‘wet pan’’ and poured into brick molds to dry in the sun before being fired by wood in beehive kilns.

The process of extracting clay, which was mined in strip mines as well as in underground mines, was modernized from 1895 to 1915. Under the new mining methods, clay was hauled from the mines by locomotives to giant crushers and moved on conveyors to local manufacturing plants or to barges on the Ohio River or, later, to the railroad for transporting to other parts of the country where it was in great demand. The demand declined precipitously after World War I as shipping costs increased and synthetic materials began to replace clay products in roads and buildings. Clay is no longer mined in West Virginia, despite an estimate in the 1980s by the West Virginia Geologic Survey that 1.5 billion tons of high-quality clay was still available in Hancock County alone.

This Article was written by Jeanne Grimm

Last Revised on June 21, 2012

Sources

Hayes, E. L. Illustrated Atlas of the Upper Ohio River and Valley from Pittsburgh, PA. to Cincinnati, OH. Philadelphia: Titus, Simmons & Titus, 1877.

McCue, John B., et al. Clays of West Virginia. Charleston: West Virginia Geological & Economic Survey, 1948.

Welch, Jack. History of Hancock County. Wheeling News Litho. Co., 1963.

New Cumberland, West Virginia: People and Places. New Cumberland: Hancock Courier Printing, 1989.

Cite This Article

Grimm, Jeanne "Clay Mining." e-WV: The West Virginia Encyclopedia. 21 June 2012. Web. 02 May 2024.

Comments?

There aren't any comments for this article yet.

Click here to read and contribute to the discussion →